Sky Greens opened on October 12, 2012 and claims to be the first economically viable vertical farm in the world. Sky Greens started as a 3.2-acre-collection of 100 three-story glass towers housing racks of Chinese cabbages, bak choi, and other leafy green vegetables.

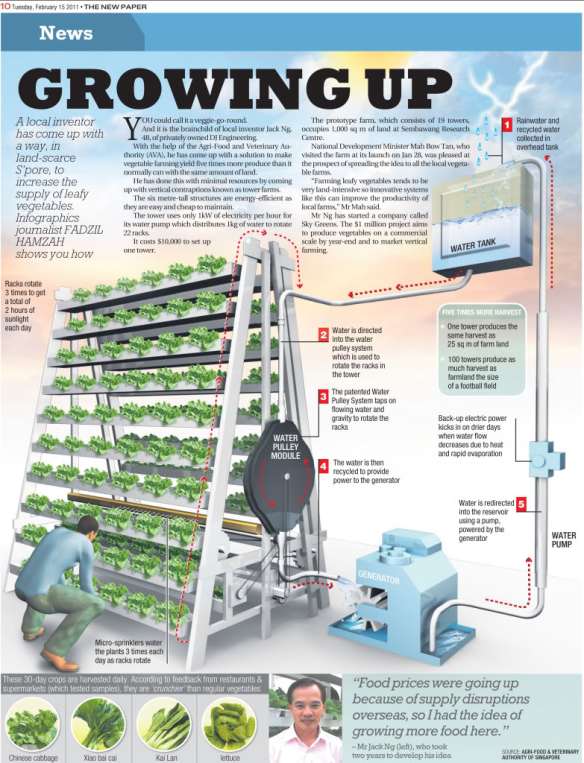

As of August 2014, it has grown to 600 towers. The driving force behind the initiative is entrepreneur Jack Ng. Ng, an engineer by training, put his mind to making the amazing system detailed in the image below.

Go back and read this article on our blog and understand how the picture below will work,

Go back and read this article on our blog and understand how the picture below will work,

Ng claims that he fields ¼ the operating costs of a traditional farm in Singapore. Energy comes from a gravity-powered water wheel and a closed loop hydraulic system. These savings don’t just come from his efficient design, but the farm’s proximity to market reduces transportation and fuel costs as well.

Not only has he cut costs, but Ng has increased efficiency. Sky Greens estimates that it is somewhere between 5 and 10 times more productive per unit of area compared to traditional farms in Singapore. Ng’s product has also earned a higher price point than competing imports (currently 5-10% more expensive than local greens, a significantly lower percentage than the 40% cost discrepancy of his 2009 prototype).

Ng’s towers produce more and even use less energy. The efficient design optimizes natural light usage and Sky Greens only spent an estimated $360/month ($3/tower) on electricity for its original 100 towers. Ng also lowers input costs by recycling water and nutrients.

Despite the price difference between Sky Greens’ produce and imports, people in Singapore have responded positively to the fresh, local vegetables. It takes just three hours from harvest for Sky Greens produce to hit the shelves. On the other hand, imported vegetables take three days to three weeks says Eco-Business.

Sky Greens has been successful enough that Ng plans to build to 2,000 towers in the coming years, bringing the total cost of the project to $28 million (USD), according to Eco-Business.

Additionally, interested parties, like local farmers, can also buy the smaller versions of the towers (2m-by-3m) for $15,000. It is worth noting that though by now these towers are a tried and tested model, they do not even begin to compete in price to some of the other personal growing units on the market.

Knowing this, and knowing that Sky Greens’ 200 gram bag of xiao bai cai retails for $1.25, the Urban Vertical Project has made some very, very rough calculations (Thank you to Eco-Business and Reuters for the data that is out there).

With 600 towers producing a ton/day, assuming that the only product was full retail xiao bai cai, Sky Greens grosses $2,281,250/year.

Knowing the cost to build 2000 towers is an estimated 28 million, we find that 600 towers costs S11.4 million. Energy costs top off at just under $26 thousand dollars each year. Notably missing from the cost side of these estimates are labor, materials,original R&D, and upkeep.

However, with just these numbers, we find that Sky Greens starts making a positive return on investment somewhere in its 5th year of operation. Though a flawed metric for a number of reasons, that sounds like a winning proposition to me. (Let me know in the comments if you’d like to see the full calculations written out or if you have more data to add) video

Singapore may be the most important country in the world for vertical farming right now.

Corporate giant Panasonic’s new project debuted just this week and challenges exactly what the country knows about its food supply.

This is a monster blog post, but there’s a lot of information synthesized here you won’t find anywhere else. I’m going to walk you through why Singapore is important, then I’m going to show you what is happening there with Panasonic and another company called Sky Greens, and then I’m going to explain what that might mean for the evolution of urban vertical farming.

No scholar could come up with a better hypothetical test case for vertical farming than the realities in Singapore. Key conditions indicating the success or even the possibility of an industrial vertical farm include:

- Dense and urban population (Singapore is an island a little more than 3 times the size of Washington, DC with a population of 5.6 million people. Their population is 100% urbanized)

- Production proximity to market (New, government-sponsored industrial parks allow companies to build their businesses on the island)

- Existing infrastructure (Singapore is a developed, high-tech country whose purchasing power parity ranks 41st in the world)

- Cheap energy (Energy is reliable and affordable, especially when supplemented with renewable resources)

- Legislative Support (Singapore’s government not only has the laudable sustainability goals of 20% self-sufficiency in the coming years, but also established a 20 million dollar fund to boost domestic food production. This helps enormously in the face of insane vertical farming start-up costs.)

- Local Demand (Expensive imports from China and Japan currently fill Singapore’s supermarkets. Singapore only produces 7% of the produce it consumes.)

Singapore embodies each of these conditions better than almost anywhere else on the planet and I’d be hard pressed to argue that what works here, in this first battleground, is not going to affect the rest of the vertical farming industry. To see what might be working, let’s first look at the older of the two companies, Sky Greens. Conclusion

So here we have two very different models. Sky Greens is as established as a company can hope to be in the vertical farm industry and is using a unique approach that has been at least successful enough to build 500 three-story high towers in less than two years. On the other hand, we have Panasonic’s new venture that relies on older, more traditional greenhouse technology.

There are positive and negative aspects to each model, but as competition for the local market presses these two companies against each other, those watching the vertical farming industry can hope to see even more cost effective innovation. Who knows, maybe each will develop their own niche vegetable markets specialized to produce the leafy green most suited to their specific growing methodology?

Either way, Singapore is a unique environment and what happens here is important.

Singapore has the second densest population in the world, as ranked by the World Bank, and all the sustainability problems associated with that density. Whereas fields and open space are almost always cheaper in land-rich countries like the United States, making vertical farming far from cost effective, “Singapore could be a special case, where land value is so exceptionally high, that you have no choice but to go vertically” says Gene Giacomelli, a plant scientist at the University of Arizona, who directs their the Controlled Environment Agriculture Center NPR reported.

Not only are the conditions right, but Singapore’s government is fully supportive of these ventures. The government recognizes that food security and sustainability goals are so much easier to reach with local production. Perishable, imported items like vegetables, which cannot be stored for long periods of time, are now grown with such proximity to the point of consumption that shipping becomes almost a non-factor (3 hours in Sky Greens’ case).

One of the most important critiques of vertical farming is that the systems are not compatible with fundamental food supply crops like grain and rice. While that is true, at least for now, for Singapore to just replace its perishable imports with local production will have an enormous impact on both its economy and its sustainability measures.

By seeing what works in a country that is so supportive and in need of vertical farming, others can replicate and build off of successful models instead of wasting time on what has already been shown to be less efficient.

We’ll be able to see if pushing new technologies like Sky Greens is the answer to the world’s hunger challenges (9 billion mouths to feed by 2050) or if we are already able to address them with tweaked versions of what we have like Panasonic. In a future post, I’ll examine how these two models fit into different thinkers’ visions of the future of farming.

Plus, each of these farms are doing really cool and innovative things for agriculture!

Stay tuned to win media library build this to the best of their abilities to gather the data for ourselves and any DIY people who want to follow along, will start with a small one and then build a larger one.

No comments:

Post a Comment